|

|

|

|

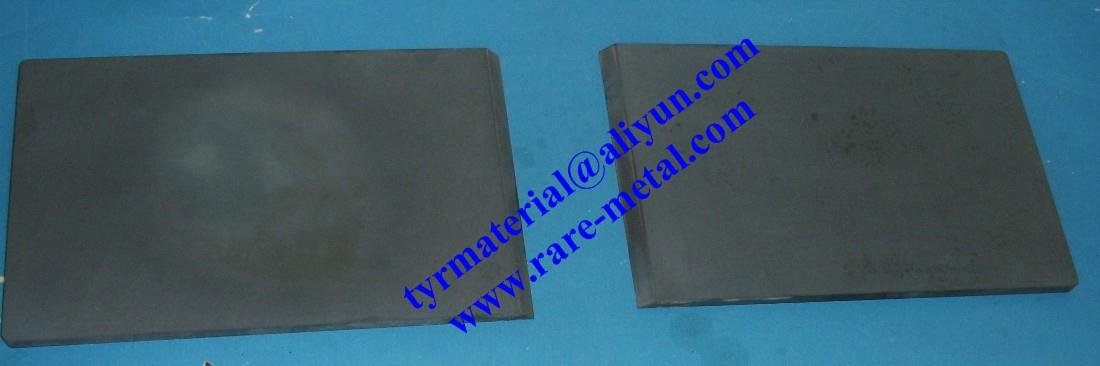

Indium Tin oxide (In2O3-SnO2) ITO sputtering target CAS 50926-11-9

Model No.︰

ITO

Brand Name︰

TYR

Country of Origin︰

China

Unit Price︰

US $ 200 / pc

Minimum Order︰

1 pc

Product Description

Indium Tin oxide (In2O3-SnO2) ITO sputtering targets

Purity: 99.99%

composition: Per requested from customer

In2O3/SnO2=90/10wt

In2O3/SnO2=50/50wt,

In2O3/SnO2=60/40wt

Diameter: 355.6mm (14") max.

Single piece Size: Length: <500mm, Width: <250mm, Thickness: >1mm, if larger size than this, we can do it as Tiles joint by 45 degree or 90 degree

Shape: Discs, disks, step disk, delta, plate, sheets or made per drawing

Density: RD>99%

Made sputtering targets method: hot pressing (HP), hot/cold isostatic pressing (HIP, CIP), and vacuum melting, vacuum sintering

Indium tin oxide (ITO, or tin-doped indium oxide) is a solid solution of indium(III) oxide (In2O3) and tin(IV) oxide (SnO2), typically 90% In2O3, 10% SnO2 by weight. Its melting point is 1526-1926 oC , Density, 7.120–7.160 g/cm3, Color (in powder form): Pale yellow to greenish yellow,

depending on SnO2 concentration

It is transparent and colorless in thin layers while in bulk form it is yellowish to grey. In the infrared

region of the spectrum it acts as a metal-like mirror.

Indium tin oxide is one of the most widely used transparent conducting oxides because of its two chief

properties, its electrical conductivity and optical transparency, as well as the ease with which it can be

deposited as a thin film. As with all transparent conducting films, a compromise must be made between

conductivity and transparency, since increasing the thickness and increasing the concentration of charge

carriers will increase the material's conductivity, but decrease its transparency.

Thin films of indium tin oxide are most commonly deposited on surfaces by physical vapor deposition.

Often used is electron beam evaporation, or a range of sputter deposition techniques.

Applications:

ITO is often used to make transparent conductive coatings for displays such as liquid crystal displays, flat

panel displays, plasma displays, touch panels, and electronic ink applications. Thin films of ITO are also

used in organic light emitting diodes, solar cells, antistatic coatings and EMI shieldings. In organic

light-emitting diodes, ITO is used as the anode (hole injection layer).

ITO films deposited on windshields are used for defrosting aircraft windshields. The heat is generated by

applying a voltage on the film.

Thin film interference caused by ITO defrosting coating on an Airbus cockpit window. The film thickness

is non-uniform on purpose, preventing uneven removal of ice/frost.

ITO is also used for various optical coatings, most notably infrared-reflecting coatings (hot mirrors) for automotive, and sodium vapor lamp glasses. Other uses include gas

sensors, antireflection coatings, electro wetting on dielectrics, and Bragg reflectors for VCSEL lasers.

ITO was also used as a sensor coating in the later Kodak DCS cameras, starting with the Kodak DCS 520,

as a means of increasing blue channel response.

ITO thin film strain gauges can operate at temperatures up to 1400 °C and can be used in harsh

environments, e.g. gas turbines, jet engines, and rocket engines.

The primary advantage of ITO compared to AZO as a transparent conductor for LCDs is that ITO can be

precisely etched into fine patterns. AZO cannot be etched as precisely: It is so sensitive to acid that it

tends to get over-etched by an acid treatment.

Another benefit of ITO compared to AZO is that if moisture does penetrate,TO will degrade less than

AZO.

composition: Per requested from customer

In2O3/SnO2=90/10wt

In2O3/SnO2=50/50wt,

In2O3/SnO2=60/40wt

Diameter: 355.6mm (14") max.

Single piece Size: Length: <500mm, Width: <250mm, Thickness: >1mm, if larger size than this, we can do it as Tiles joint by 45 degree or 90 degree

Shape: Discs, disks, step disk, delta, plate, sheets or made per drawing